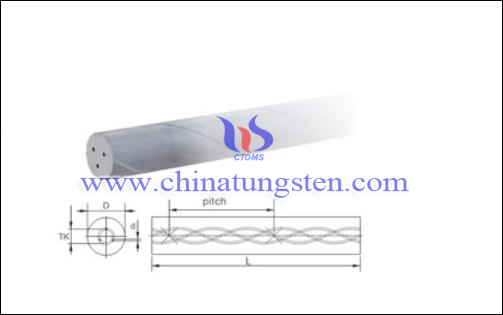

硬质合金三螺旋孔圆棒制作工艺流程

硬质合金三螺旋孔圆棒的制造技术,其关键是螺旋孔的成形,主要是通过金属粉末的注射成形技术。其工艺是:将金属粉末与石蜡的混合物注射成型,然后通过烧结去除石蜡,得到高密度的硬质合金螺旋孔棒。金属注射成型工艺的流程为:混料→制胶→注射料→注射成型(模具)→生坯→解除粘结剂→烧结→烧结后处理→产品。用金属粉末注射成形生产的硬质合金螺旋孔棒具有高效、优质、精密、低耗等优点。

常规规格表(mm)

| 粗坯直径 | 公差 | 研磨直径 | 孔距 | 公差 | 孔径 | 公差 | 螺距 | 圆心偏离 | 长度 |

| 6.3 | +0.2/+0.8 | 6.0 | 2.05 | ±0.15 | 0.50 | ±0.15 | 22.46 | ±4° | 330+2 |

| 7.3 | +0.3/+1.0 | 7.0 | 2.25 | ±0.15 | 0.65 | ±0.15 | 26.21 | ±4° | 330+2 |

| 8.3 | +0.3/+1.0 | 8.0 | 2.45 | ±0.15 | 0.65 | ±0.15 | 29.95 | ±4° | 330+2 |

| 9.3 | +0.3/+1.0 | 9.0 | 3.05 | ±0.15 | 0.75 | ±0.15 | 33.70 | ±4° | 330+2 |

| 10.3 | +0.3/+1.0 | 10.0 | 3.35 | ±0.15 | 0.80 | ±0.15 | 37.44 | ±4° | 330+2 |

| 11.3 | +0.3/+1.0 | 11.0 | 3.45 | ±0.25 | 0.80 | ±0.15 | 41.18 | ±4° | 330+2 |

| 12.3 | +0.3/+1.0 | 12.0 | 3.95 | ±0.25 | 0.80 | ±0.15 | 44.93 | ±4° | 330+2 |

| 13.3 | +0.3/+1.1 | 13.0 | 4.15 | ±0.25 | 0.90 | ±0.20 | 48.67 | ±4° | 330+2 |

| 14.3 | +0.3/+1.1 | 14.0 | 4.45 | ±0.25 | 0.90 | ±0.20 | 52.42 | ±4° | 330+2 |

| 15.3 | +0.3/+1.1 | 15.0 | 4.85 | ±0.25 | 1.00 | ±0.20 | 56.16 | ±4° | 330+2 |

| 16.3 | +0.3/+1.2 | 16.0 | 5.25 | ±0.25 | 1.10 | ±0.20 | 59.90 | ±4° | 330+2 |

| 17.3 | +0.3/+1.2 | 17.0 | 5.65 | ±0.25 | 1.20 | ±0.20 | 63.65 | ±4° | 330+2 |

| 18.3 | +0.3/+1.2 | 18.0 | 6.05 | ±0.25 | 1.20 | ±0.20 | 67.39 | ±4° | 330+2 |

| 19.3 | +0.3/+1.2 | 19.0 | 6.35 | ±0.35 | 1.40 | ±0.25 | 71.14 | ±4° | 330+2 |

| 20.3 | +0.3/+1.2 | 20.0 | 6.75 | ±0.35 | 1.40 | ±0.25 | 74.88 | ±4° | 330+2 |

| 21.3 | +0.3/+1.2 | 21.0 | 7.05 | ±0.35 | 1.50 | ±0.25 | 78.62 | ±4° | 330+2 |

| 22.3 | +0.3/+1.2 | 22.0 | 7.35 | ±0.35 | 1.70 | ±0.25 | 82.37 | ±4° | 330+2 |

| 24.3 | +0.3/+1.2 | 24.0 | 7.55 | ±0.45 | 1.75 | ±0.25 | 89.86 | ±4° | 330+2 |

| 25.3 | +0.3/+1.2 | 25.0 | 7.65 | ±0.45 | 1.75 | ±0.25 | 93.60 | ±4° | 330+2 |

| 26.3 | +0.4/+1.3 | 26.0 | 7.75 | ±0.45 | 1.75 | ±0.25 | 97.34 | ±4° | 330+2 |

| 28.3 | +0.4/+1.3 | 28.0 | 8.55 | ±0.45 | 2.00 | ±0.30 | 104.83 | ±4° | 330+2 |

| 30.3 | +0.4/+1.3 | 30.0 | 9.45 | ±0.55 | 2.00 | ±0.30 | 112.32 | ±4° | 330+2 |

| 32.3 | +0.4/+1.3 | 32.0 | 10.45 | ±0.55 | 2.00 | ±0.30 | 119.81 | ±4° | 330+2 |

厦门中钨在线科技有限公司一直致力于生产高质量的硬质合金产品,如果您有任何相关的问题或者询价,欢迎致信sales@chinatungsten.com, sales@xiamentungsten.com, 或致电:0592 5129696