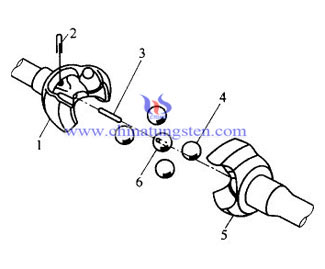

Tungsten Karbür Top for Universal Joint

Universal Joint

Universal joints have movement only in the vertical plane when they are used for lon¬gitudinally mounted propeller shafts and transverse rear mounted drive shafts. When these joints have been used for front outer drive shaft they have to move in both the vertical and horizontal plane to accommodate both vertical suspension deflection and the swivel pin angular movement to steer the front road wheels. The compounding of angular working movement of the outer drive shaft steering joint in two planes imposes large and varying working angles even when the torque is being transmitted to the stub axle. Due to the severe working conditions, special universal joints known as constant velocity joints are employed. These joints have been designed to absorb torque and speed fluctuations and to operate reliably with very little noise and wear having long life.

Universal joints are capable of transmitting torque and rotational motion from one shaft to another when their axes are inclined to each other by some angle, which may constantly vary under working conditions. Universal joints are incorporated in the of vehicle's transmission system to perform three basic applications.

(a) Propeller shaft end joints between longitudinally front mounted gearbox and rear final drive axle.

(b) Rear axle drive shaft end joints between the sprung final drive and the unstrung rear wheel stub axle.

(c) Front axle drive shaft end joints between the sprung front mounted final drive and the unstrung front wheel steered stub axle.

Classification

Universal joint in the reverse direction is not significantly flexible joint. It can be divided into non-constant velocity joint, quasi-constant velocity joint and constant velocity joint. Wherein the constant velocity joint is divided into:

Fork-ball Constant Velocity Joint

Universal joint combined by raceways fork ball and Tungsten Karbür Top. And the arcuate groove raceway fork-type ball joint means righteousness Tungsten Karbür Top raceway on an arc-type universal joint. Its structure is characterized by sections made on the active fork ball and have driven arc groove formed between the two fitted together after four carbide ball raceway, accommodating a total of four carbide ball inner race. Centering carbide ball mounted within the spherical recess primary, driven fork center. Straight groove raceway-type ball joint fork means Tungsten Karbür Top rolling on a straight groove raceway-type universal joint. Its structure is characterized by the two fork ball to do a straight groove, straight groove and each axis is inclined relative to the center line, and the same tilt angle and symmetrical to each other. Built in the raceway between the two fork ball has four Tungsten Karbür Top.

Ball Basket Constant Velocity Joint

According to joint axial movement can, and can be divided into axial telescopic type (fixed) Ball Basket universal joints and scalable type constant velocity joint. Within the structure of the inner surface of the fixed type Ball Basket universal joints star sleeve spline connection with the drive shaft, its outer surface is formed with an actuate six internal Tungsten Karbür Top raceway, outer raceway made on the inner surface of the spherical shell. Each loaded carbide ball inside a star with six sets of roller spherical shells fitted together after the formation, and then Cage makes six Tungsten Karbür Tops in the same plane. Power comes out through by the Tungsten Karbür Top and spherical shell. Structural features can be telescopic type constant velocity joints are in the inner wall of the cylindrical shell of the star and the external cylindrical sleeve made straight slot, built-in two raceway fitted together after the formation of Tungsten Karbür Top. Tungsten Karbür Top is also mounted in the bore of the cage. Star housing bore splinted for connection with the input shaft. This structure allows the sleeve and the star-shaped shell simple relative movement in the axial direction.