Q&A

Tungsten carbide also called tungsten cemented carbide, cemented carbide or simply carbide.Tungsten carbide (WC) is an inorganic chemical compound containing equal parts of tungsten and carbon atoms. In its most basic form, tungsten cemented carbide is a fine gray powder, but it can be pressed and formed into shapes for use in industrial machinery, cutting tools, abrasives, other tools and instruments, and jewelry. Tungsten cemented carbide can be pressed and formed into shapes from fine gray powder, which is considered to be its most basic form.The applications of tungsten cemented carbide are widely reflected in industrial machinery, wear resistent tools, abrasives as well as men' s jewelry.

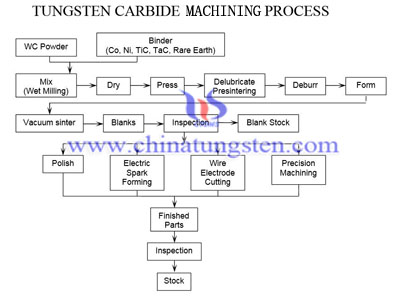

Tungsten carbide machining begins with the composition of a specific tungsten carbide powder mixture - tailored for the application. The tungsten carbide powder is compacted into a form. In a high-temperature sintering furnace, the tungsten carbide structure of the blank is shaped at precise temperatures for strictly defined periods. During this heat treatment, the tungsten carbide blank undergoes shrinkage of some 50% in volume. The tungsten carbide component gains its final finish by additional grinding, lapping and/or polishing processes.

Tungsten carbide properties of a particular "grade" of carbide are determined by its composition (its constituents and their relative amounts), the size distribution of the tungsten carbide grains after sintering, the binder metal type and content, the quality of the raw materials used, and the workmanship with which the material is made. Those most commonly measured to assess quality and define application areas are described below.

For the more detail of tungsten carbide grade, please kindly visit our website of Traditional Grade

Tungsten carbide rod are mostly applied for drill bits, end mills, and reamers with sub-micron grain grade YG10X, for non-ferrous precision cutting and wood cutting with grade YG6X, and for fiberglass reinforced plastics, titanium alloys, hardened steel with ultra-fine grain grade YG8X, etc. Tungsten carbide rods include rods with the shapes of round, rectangular and square, solid rods and rods with one or more straight or coolants. Tungsten carbide rods are mostly applied for end mill and drill with sub-micron grain grade YG10X, for non-ferrous precision cutting and wood cutting with Sub-micron grain grade YG6X, and for fibreglass reinforced plastics, titanium alloys, hardened steel with Ultra-fine grain grade YG8X, ect.

Tungsten carbide balls are also called cemented carbide balls, bearing balls or just simply carbide balls. The applications of tungsten carbide balls are extremely broad, such as: precise bearing balls, instruments, meters, pen, spraying machines, pumps, machinery parts, valve seals, brake pump, extruding hole, oil, hydrochloric acid lab, hardness measuring instrument, fishing gear, with heavy, ornamented, finished, and some other high-end industry! Tungsten carbide balls are ideal for applications where extreme hardness must be accompanied by high resistance to wear and impact. They are well-suited to elevated temperatures, corrosion, humidity, abrasion, and poor lubrication conditions.

Tungsten carbide mechanical seals are being used increasingly on fluid pump to replace packed gland and lip seal. tungsten carbide mechanical sealPump with mechanical seal perform more efficiently and generally perform more reliably for extended periods of time. Tungsten carbide mechanical seal is provided to prevent pumped fluid from leaking out along the drive shaft. The controlled leakage path is between two flat surfaces associated with the rotating shaft and the housing respectively. The leakage path gap varies as the faces are subjected to varying external load which tend to move the faces relative to each other.

Tungsten carbide button is widely used as the most popular mining bits tool in modern industries, therefore, they are also named tungsten carbide mining bits, tungsten carbide button bits or just tungsten carbide mining buttons, etc. And as their material is cemented carbide, so cemented carbide buttons are also widely used among the users. Cemented carbide buttons are used in the coal cutter drilling tools, mine machinery tools and road maintenance tools for snow clearing and road cleaning. Carbide mining button bits are widely applied for rock tools, mining tools for use in quarrying, mining, tunneling, and civil constructions.

Tungsten carbide nozzle, made of high grade tungsten carbide, is one of the spray nozzles. In another way saying, tungsten carbide nozzles are usually used to sandblasting, therefore, users also call them tungsten carbide sandblasting nozzles. The hardness reached over HRA90 degree while the anti-bending degree reached over 2300N/mm. On machining tungsten carbide spray nozzle, we do the precision grinding and surface treatment to achieve Ra0.1 of the bore roughness and the Ra0.025 of the R place of both ends. There is a scientific curvature radius design in the both entrance. This design can ensure a smooth transit of the thread.