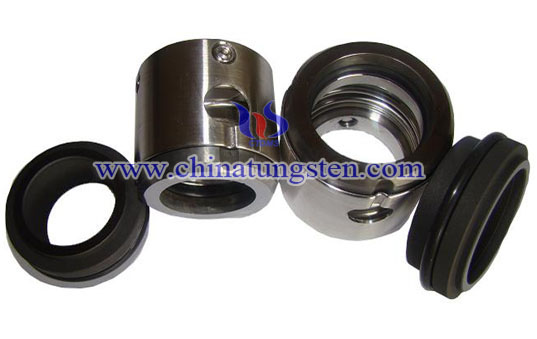

Tungsten Carbide Combined Seals Ring

Introduction

Usually choose tungsten carbide combined seals ring to achieve the desired sealing effect, which is combined by two or more kinds seals. There is a group for three kinds seals, and also have a group for five kinds seals.

Notes

In the design and manufacture of mechanical seals, because of the conditions for usage, the rotating ring or stationary ring are required use tungsten carbide materials. And in order to saving costs for wear resistant material, it is usually being designed to combined seals ring. Especial for the more complex compensation rotating ring or compensation stationary ring, if there were used the general tungsten carbide seals, which with poor technology, more difficult processing. So it wills often using the tungsten carbide combine seals ring. In general, we are usually using hot mounting tungsten carbide combine seals ring. It should choice proper interference fit between tungsten carbide rings and stainless steel seat ring. If excessive interference, the tungsten carbide seals ring will be broken under the large contact stress; if Interference is too small, the tungsten carbide seals ring will be released under the usage. So it is better to choose H7/u6 to fit it. It should be heated when the seals combined, after mosaic seat hole heated and swell, put in the tungsten carbide seals ring, after cooling makes both of interference under fixedly connected together. At last, the end of combined seals ring should be grinding and polished.

Features

- With different outer diameter, inner diameter, quantity, force method, installation and demolition method.

- Material, width, thickness, processing method and heat treatment are in the same way with general carbide seals.

- Multiple labyrinth effect.

- To prevent the possibility of foreign matter into the bearing, decrease the leakage liquid.

- Extend the time for seal liquid in the seal chamber, and then extend the span life of bearing.

- Reducing the use and maintenance costs of enterprise.