Tungsten Carbide Button Life

Description

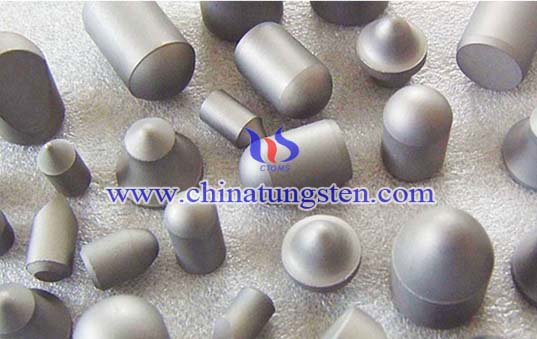

Tungsten carbide button is not only widely applied to the oil rig and snowplow but also to the cutting tool, mining machinery, the equipment of road maintenance and coal drilling tools. In the mine, the buttons are mainly used as mining tools in quarrying, mining, and tunnels and civil buildings.

Improve service life

In order to improve overall properties and extend the service life of buttons, the key point is to control the stability of alloy quality. It can be seen from the product properties of alloy in China and abroad that the composition of the alloy is basically the same. In order to ensure the stability of button quality during the production, we should start from three main aspects:

Firstly., we should control the size of the crystal and the uniformity of distribution in order to avoid large crystal. It needs to start from the control of the grinding of the raw material WC powder and the size distribution to ensure that the size is distributed uniformly and is similar to alloy crystal grain size. Only when alloy crystal is uniform without large crystal, the quality of button can be stable.

Secondly, we should strictly control the quality fluctuations during the alloy production, from the traditional rubber process to paraffin, PEG process, to facilitate the precise control of the carbon. Meanwhile, the storage environment and time of mixture and pressed compact should be strictly under control to avoid the fluctuation of carbon content which will affect the quality of product.

Thirdly, the advanced production process should be adopted: pressure sintering process. As for low cobalt alloy, it is difficult to have a further improvement of the densification of alloy and reduce the inner tissue defects in the process of hydrogen sintering and vacuum sintering because cobalt content is relatively low. The improvement of density, intensity, durability and fracture toughness is difficult as well. At the same time, it is very important to specify the appropriate sintering process curve and strictly control the detailed operation of the sintering. It is crucial for the of stable quality of button. The property of tungsten carbide button is so stable that button can keep high hardness and high strength even at high temperatures. WC-Co tungsten carbide is particularly outstanding in machining.