Tungsten carbide acicular drill is new technologies develop by our drilling engineering since our reform. When used in hard rock, the acicular drill is more superior to steel, which with high efficiency, good quality, low cost, low consumption of steel and other advantages. Acicular drills and diamond drilling supporting the implementation of tiered drilling, for promote small-caliber diamond drilling has important significance.

Tungsten Carbide Acicular Drill Advantages

The advantages of acicular drill include the following:

1、High Efficiency

With self grind edge features, acicular drill take many rock’s free surfaces, it is more conducive to breaking rock. Drilling in the grade of 6 to 7 rock, the efficiency is one times than conventional carbide.

2、High Quality

Aperture are rules and uniformly, drilling with small curvature. The take rate of limestone core could reach to 80%~90% in the grade of 6 to 7.

3、Long Lifetime

Φ56mm acicular drill in seven limestone formation drilling, average bit life is 9.92m, it is three to five times than normal carbide drill, and the highest life is 23.98m.

4、Less Consumption of Steel

Acicular drill is less 60% than conventional carbide in per meter drilling and abrasive costs.

5、Reused Bit Material

Low cost in the drill manufacture, a drill bit can be reused 2 to 3 times.

6、Easy To Operate

Small labor intensity, inner hole is cleaning, security is relatively good.

7、Cooperate With Diamond Drill, Implement Tiered Drilling

Acicular drill drilling in some 6 to 7 and section 8 rocks, are able to achieve good results, expanding the application scope.

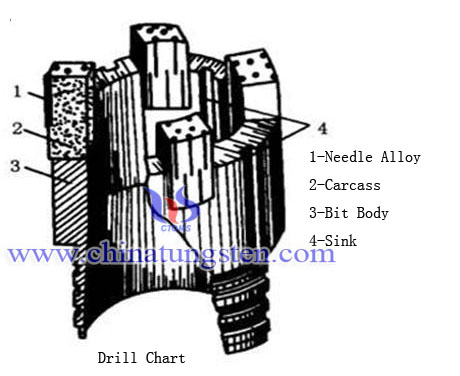

Tungsten carbide acicular drill is a kind of drill, which is put the sintered needle alloy block welded onto a blank bit. It consists of needle alloy, carcass and bit body, the basic structure as shown in the following:

|

1、Processing of Needle Alloy Block

The general grade of tungsten carbide acicular drill is YG8、YG6、YG4C、YA6 and so on. The fflexural strength is bigger than1.4GPa, hardness is bigger than 88HRA. The diameter of acicular drill is1.8~2.2mm, the length is 10~16mm. the outer and inner diameter of drill in the 12~16mm are able to protect the diameter. Intermediate carcass lip surface using a length of 10 ~ 12mm. Carcass material is mixed with the powder material uniformly iron, copper and zinc separate made. Iron plays a role in skeleton in the carcass; copper for the metal bonded during sintering iron powder particles to stick together, and can be a good needle alloy welding. Zinc separate is a lubricant, can improve the matrix-forming properties. Matrix formula: 70% to 80% iron, 30% to 20% copper, 0.5% zinc separate was added to 1% of the total mix.

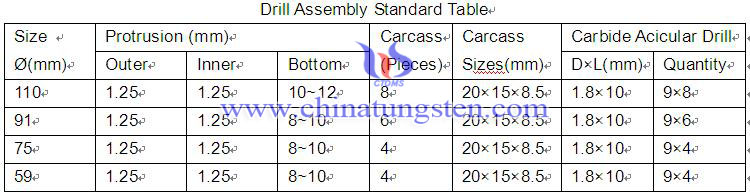

2、Drill Assembly

According to different carcass diameter drill bit body assembly and inserts welded. Supporting the drill can be used as needed in the following table:

Drill diameter size range as shown the following:

When the drill assembly, should pay attention to the following questions:

(1) Mosaic block on the tire of the bit body groove, available on the milling machine or planer processing, the width should be the width of the carcass kiss together, do not leave any gaps.

(2) Should be the same thickness as the tire block mounted on the same drill. To ensure consistency within each block tread diameter, prevent the outer diameter of excessive wear, impact drill life. Therefore, we should adopt heart sons positioning method.

(3) Carefully measure the outside diameter of the drill bit, the error should be controlled within 0.3mm.

(4) Flat welding temperature should be controlled at 930 ~ 1100 ℃. Gun fire can not live directly on the carcass, to avoid damage to tires body performance.

More Info>>

1.Tungsten Carbide

2.Tungsten carbide Balls

3.Tungsten carbide Burrs

4.Tungsten Carbide Inserts

5.Tungsten Carbide Plates

CHINATUNGSTEN ONLINE has been specialized in manufacturing tungsten products, especially cemented carbide products for more than 20 years. If you have any inquires concerning the products in this website, please do not hesitate to e-mail us by : sales@chinatungsten.com

Tungsten Information[Tungsten Information ][Tungsten Catalogs][Tungsten Dictionary]

[Tungsten News][Tungsten Videoes Bank][Tungsten Pictures' Bank][Tungsten Directory]

Chinatungsten Group[ChinaTungsten] [Tungsten Alloy Manufacturer] [Tungsten News] [Paper Weight] [Tungsten Copper] [Tungsten] [Molybdenum Products] [Tungsten Alloy]

[Tungsten Carbide Jewellery] [Tungsten Dart] [Dart Shop] [Tungsten Fishing Sinker] [Tungsten Powder] [Tungsten Metal] [Metals Price]

Address: 3F, No.25 WH Rd., Xiamen Software Park Ⅱ, FJ 361008,China

Phone:+86-592-5129696,+86-592-5129595; Email:sales@chinatungsten.com

Certified by MIIT:闽B2-20090025 闽ICP备05002525号-1

Copyright©1997 -

ChinaTungsten Online All Rights Reserved