Binderless tungsten carbide refers to a class of high wear-resistant WC hard alloys containing less than 0.5% by mass of Co., which has higher hardness, wear resistance and resistance than traditional WC-Co tungsten carbide. Corrosive and superior polishing characteristics, while reducing the cost of raw materials, and reducing the impact of Co6tl radioactivity on the human body and the environment. Since the ordinary particle size WC powder cannot produce a higher density bulk by the conventional sintering method when the Co content is extremely low, the ultrafine WC powder can not only obtain an alloy of nearly full dense structure but also the hardness, strength and toughness of the material. Will be greatly improved, so the unbonded phase ultra-fine tungsten carbide becomes an important research direction of tungsten carbide.

| Density(g/cm3) | Hardness(HV) | T.R.S.(MPa) | Toughness(MPa/m2) | Specific Heat(J/mol.K) | ||

| >15.4 | >2600 | >830 | 5.9 | 35.4 | ||

| Thermal Conductivity | Thermal Expansion | Resistivity | Corrosion Resistance | |||

| 120(W/m.K) | 4.5x10-6/℃ | 17x10-6ohm.cm | H2NO3,HCL,H2SO4,HF,Alkali | |||

More Info>>

1.Tungsten Carbide

2.Tungsten carbide Balls

3.Tungsten Carbide Rods

4.Tungsten Carbide Inserts

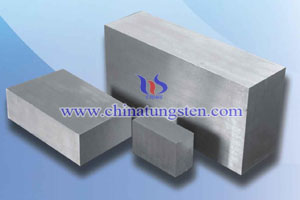

5.Tungsten Carbide Plates

CHINATUNGSTEN ONLINE has been specialized in manufacturing tungsten products, especially cemented carbide products for more than 20 years. If you have any inquires concerning the products in this website, please do not hesitate to e-mail us by : sales@chinatungsten.com

Tungsten Information[Tungsten Information ][Tungsten Catalogs][Tungsten Dictionary]

[Tungsten News][Tungsten Videoes Bank][Tungsten Pictures' Bank][Tungsten Directory]

Chinatungsten Group[ChinaTungsten] [Tungsten Alloy Manufacturer] [Tungsten News] [Paper Weight] [Tungsten Copper] [Tungsten] [Molybdenum Products] [Tungsten Alloy]

[Tungsten Carbide Jewellery] [Tungsten Dart] [Dart Shop] [Tungsten Fishing Sinker] [Tungsten Powder] [Tungsten Metal] [Metals Price]

Address: 3F, No.25 WH Rd., Xiamen Software Park Ⅱ, FJ 361008,China

Phone:+86-592-5129696,+86-592-5129595; Email:sales@chinatungsten.com

Certified by MIIT:闽B2-20090025 闽ICP备05002525号-1

Copyright©1997 -

ChinaTungsten Online All Rights Reserved