The fine-grained WC powder with a particle size of 0.2 μm was used as a raw material, and was sintered at 1230 ° C by ball milling, and a high-hardness, high-density ultra-fine non-bonded phase hard alloy was prepared by hot pressing at 890 MPa. The phase composition, density, microhardness and microstructure of the alloy were analyzed.

1. The original WC powder is ball milled in SYQ-2 high-energy ball mill. The number of ball mills is 400r/min, the ball is tungsten carbide ball, the ball-to-batch ratio is 10:1, the ball milling time is 6h, and the ball is vacuumed before ball milling. Argon gas protection during ball milling.

2. The powder after ball milling is uniformly mixed with 2% liquid paraffin. The powder was made into a Ø16x12 sample under a compressive stress of 500 MPa.

3. In order to make the sample reach a high density state, avoid the pores caused by paraffin gasification during the sintering process, degass the sample after pressing, and raise the temperature to 450 ° C for 1 h at a slow heating rate, so as to be faster. After the temperature is raised to 800 ° C for 30 min, the furnace is cooled to room temperature and taken out. The whole process is protected by argon gas to ensure that the sample will not be oxidized when heated.

4. The dewaxed sample is placed in a carrier made of refractory castable, surrounded by glass powder, rapidly heated and sintered in a high temperature resistance furnace to 1230 ° C for 2 h, and argon gas is protected during the sintering process. The molten glass powder is used as a hot pressing medium at a high temperature, and hot pressing is performed on a YT27 hydraulic press with a maximum pressure of 200T. In the preheated mold, the hot pressing pressure is 890 MPa, the pressure is maintained for 10 s, and the sample is taken from the glass after hot pressing. The powder was taken out for analysis.

5. In order to avoid the decarburization phase after the alloy is sintered, a single-weight carbon powder mixed ball mill with a mass fraction of 0.1% to 0.7% is separately added to the original WC powder for sintering and hot pressing.

6. The density of the sample was determined by the drainage method; the microhardness of the WC was tested by the X-ray diffractometer and the JSM-6360LV scanning electron microscope for the WC phase composition and the microhardness tester.

Pure tungsten carbide powder with an average diameter of 0.2um was used to prepare ultra-fine binderless tungsten carbide by sintering at 1230℃ followed by hot pressing at 890 MPa, and the phase composition, density, vickers hardness and micro-structure of the tungsten carbide were studied. The results show that the tungsten carbide made of tungsten carbide powder without ball milling exhibits lower hardness and density compared with that made of milled powder. The hardness of the latter is HV2157, 15 times of that of the former, and its density is 95.1%. The morphology of fracture surface is characterized by cleavage fracture. In order to inhibit the decarburizing reaction, carbon element was added in WC powder, and XRD analysis reveals that pure tungsten carbide is obtained with a 0.35% carbon addition resulted in the hardness of HV 2480 and density of 98% for the sintered WC tungsten carbide.

1.Tungsten Carbide

2.Tungsten carbide Balls

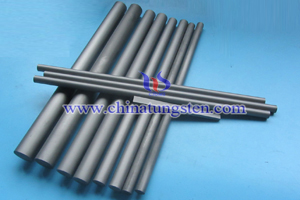

3.Tungsten Carbide Rods

4.Tungsten Carbide Inserts

5.Tungsten Carbide Plates

CHINATUNGSTEN ONLINE has been specialized in manufacturing tungsten products, especially cemented carbide products for more than 20 years. If you have any inquires concerning the products in this website, please do not hesitate to e-mail us by : sales@chinatungsten.com

Tungsten Information[Tungsten Information ][Tungsten Catalogs][Tungsten Dictionary]

[Tungsten News][Tungsten Videoes Bank][Tungsten Pictures' Bank][Tungsten Directory]

Chinatungsten Group[ChinaTungsten] [Tungsten Alloy Manufacturer] [Tungsten News] [Paper Weight] [Tungsten Copper] [Tungsten] [Molybdenum Products] [Tungsten Alloy]

[Tungsten Carbide Jewellery] [Tungsten Dart] [Dart Shop] [Tungsten Fishing Sinker] [Tungsten Powder] [Tungsten Metal] [Metals Price]

Address: 3F, No.25 WH Rd., Xiamen Software Park Ⅱ, FJ 361008,China

Phone:+86-592-5129696,+86-592-5129595; Email:sales@chinatungsten.com

Certified by MIIT:闽B2-20090025 闽ICP备05002525号-1

Copyright©1997 -

ChinaTungsten Online All Rights Reserved