Compared with traditional Co-containing tungsten carbide, the binderless tungsten carbide has higher hardness (>HRA95), and its wear resistance, oxidation resistance and corrosion resistance are considerably improved when used in certain harsh environments. It can be used to make sandblasting nozzles, electronic packaging materials, heavy-duty sliding seal wear parts, etc.; its cutting performance is about 21 times that of traditional tungsten carbide, which can be used as tool and drill material, especially for processing titanium alloy. In terms of work efficiency, it can be greatly improved.

In addition, the unbonded phase tungsten carbide has better polishability than conventional WC-Co tungsten carbide. Due to the inconsistent processing speed of WC and Co, it is difficult to obtain a smooth processing surface for conventional tungsten carbide, and the unbonded phase hard alloy without Co can obtain a very smooth processed surface, so the non-bonded phase hard alloy is particularly suitable. For precision optical molds. At present, foreign products have been available. For example, Japan Tungsten Corporation has officially launched pure WC unbonded phase carbide products, mainly used for aspherical lens molds. Compared with traditional tungsten carbides, this product has high hardness, low coefficient of thermal expansion and excellent mirror finish, and the oxidation weight gain at atmospheric pressure of 800 ° C is only about 15% of that of conventional tungsten carbide.

It is foreseeable that binderless tungsten carbide will have a very broad application prospect. However, the main raw material WC of the binderless phase tungsten carbide is a high melting point carbide (melting point up to 2900 ° C), and in the absence of a binder phase, high density cannot be obtained by conventional sintering methods such as vacuum sintering. . With the popularization of hot isostatic pressing technology in the tungsten carbide industry, combined with the invention of the submicron WC powder synthesis technology, the densification synthesis of the binderless phase tungsten carbide has become possible.

At present, the sintering technology used in research and development is mainly spark plasma sintering (SPS). SPS mainly uses the electric field formed by the application of pulsed high current to clean the surface oxides and adsorbed gases of powder particles, purify materials, activate powder surface, and improve The diffusion capacity of the powder surface is then used to heat the powder for short-time heating at a low mechanical pressure for compaction. SPS technology has the advantages unmatched by hot isostatic pressing technology: low sintering temperature (200-300 ° C lower than hot isostatic pressing), short sintering time (only 3-10 min), low energy consumption per piece, high density of sintered body The fine grain is a near-final forming technology; the operation is simple, unlike the hot isostatic pressing, which requires a very skilled operator and a special mold sleeve technology.

Now, with SPS, it is possible to prepare large unbonded phase WC superhard materials with high density (more than 98% relative density) and high hardness (up to HRA96). Studies have shown that a finer WC powder can be used to obtain a dense WC compact sintered body at a lower temperature. At present, binderless tungsten carbide is mainly based on micron or submicron raw powder. If the original WC powder is refined to the nanometer scale, the performance of the alloy will be significantly improved. For example, if 200 nm of the original WC powder is used, a pure WC sintered body having a relative density of 99.6% can be obtained at 1500 ° C using the SPS sintering technique, and at the same time has good hardness and toughness. However, finer WC grains are also liable to cause abnormal growth of crystal grains, and by adding a particle size inhibitor such as VC or Cr3C2, the WC particle size can be effectively suppressed, and the alloy properties can be further improved.

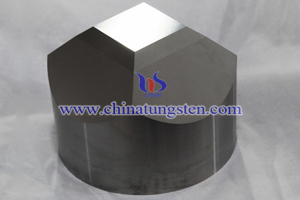

1.Tungsten Carbide

2.Tungsten carbide Balls

3.Tungsten Carbide Rods

4.Tungsten Carbide Inserts

5.Tungsten Carbide Plates

CHINATUNGSTEN ONLINE has been specialized in manufacturing tungsten products, especially cemented carbide products for more than 20 years. If you have any inquires concerning the products in this website, please do not hesitate to e-mail us by : sales@chinatungsten.com

Tungsten Information[Tungsten Information ][Tungsten Catalogs][Tungsten Dictionary]

[Tungsten News][Tungsten Videoes Bank][Tungsten Pictures' Bank][Tungsten Directory]

Chinatungsten Group[ChinaTungsten] [Tungsten Alloy Manufacturer] [Tungsten News] [Paper Weight] [Tungsten Copper] [Tungsten] [Molybdenum Products] [Tungsten Alloy]

[Tungsten Carbide Jewellery] [Tungsten Dart] [Dart Shop] [Tungsten Fishing Sinker] [Tungsten Powder] [Tungsten Metal] [Metals Price]

Address: 3F, No.25 WH Rd., Xiamen Software Park Ⅱ, FJ 361008,China

Phone:+86-592-5129696,+86-592-5129595; Email:sales@chinatungsten.com

Certified by MIIT:闽B2-20090025 闽ICP备05002525号-1

Copyright©1997 -

ChinaTungsten Online All Rights Reserved