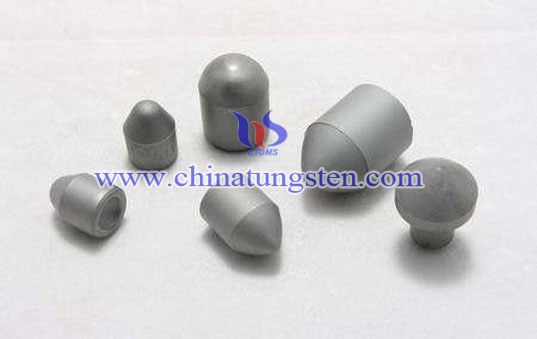

Tungsten Carbide Coal Button

Introduction

Tungsten carbide with excellent wear resistance and impact toughness, which with higher drilling speed than similar products. The long service life is 5-6 times of the grinding life of the same diameter blade head, which is beneficial to save auxiliary working hours, reduce manual labor and speed up engineering. The cemented carbide cutting coal miner and the boring machine picks, wherein the boring machine picks require higher hardness.

Application

Tungsten carbide coal buttons are mainly used in mining, tunnel construction, etc.

Grades

| Grade | Density g/cm3 |

T.R.S. MPa |

Hardness HRA |

Properties and Application |

| YG4C | 15.10 | 1800 | 90.0 | Mainly used as a impact drill for cutting soft and medium materials. |

| YG6 | 14.95 | 1900 | 90.5 | Used as electric coal drill bit, coal pick, petroleum roller bit and scraper ball bit. |

| YG8 | 14.80 | 2200 | 89.5 | As core drill, electric coal drill bit, coal pick, petroleum roller bit and scraper ball bit. |

| YG8C | 14.80 | 2400 | 88.5 | It is mainly used as a ball tooth for small and medium-sized impact drills and as a bearing for rotary exploration drills. |

| YG11C | 14.40 | 2700 | 86.5 | Most of them are used in impact drills and ball bearings for cutting high hardness materials in roller cone bits. |

| YG13C | 14.2 | 2850 | 86.5 | It is mainly used for the ball teeth used in rotary impact drills to cut medium and high hardness materials. |

| YG15C | 14.0 | 3000 | 85.5 | Cutting tool for oil cone drill bit and medium soft medium hard rock excavation. |

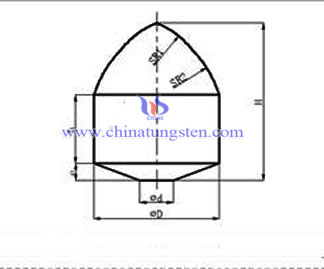

Specifications

| Type | Dimensions | Angle | |||||

| D | d | H | h | SR1 | SR2 | e | |

| YJ2428-X35 | 24 | 4 | 28 | 12.5 | 1.5 | 30 | 3.5 |

| YJ15.725 | 15.75 | 4 | 25 | 12.5 | 1 | 25 | 3.5 |