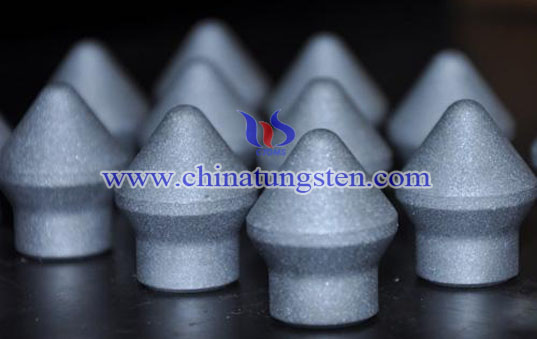

Tungsten Carbide Mushroom Button

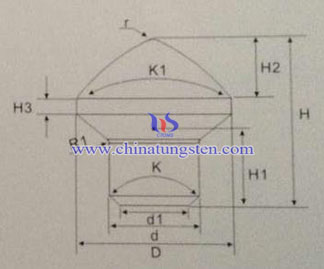

Specifications

| Type | Dimensions | |||||||||||

| SR | R | R1 | K | K1 | H | H1 | H2 | H3 | D | d | D1 | |

| Ø18x22 | 30 | 1.5 | 2 | 120° | 90° | 22 | 11 | 7.5 | 1.5 | 18 | 10 | 6.5 |

| Ø20X27 | 35 | 1.5 | 2 | 60° | 90° | 27 | 13.5 | 8.5 | 4 | 20 | 12 | 9.7 |

| Ø19X26 | 28 | 2 | 2 | 90° | 120° | 26 | 0 | 10 | 4 | 19 | 14 | 12 |

| Ø20X25 | 26 | 1.5 | 2 | 120° | 90° | 25 | 0 | 8 | 2 | 20 | 12 | 5 |

| Ø20X25 | 35 | 1.5 | 2 | 120° | 90° | 25 | 0 | 7.5 | 1.5 | 20 | 12 | 5 |

Tungsten carbide mushroom button with high wear resistance and impact toughness, it has a higher drilling speed than similar products. The ball tooth series passivation has a long service life, and its non-wear life is about 5-6 times of the grinding life of the same diameter blade head bit, which is beneficial to save auxiliary working hours, reduce manual labor and speed up engineering.

1.The raw material is made of original raw material.

2. Sintering by vacuum integrated furnace or high-pressure sintering furnace, with high overall performance, without voids.

3. Provide blank or passivated button.

4. Tungsten carbide button are widely used in mining quarrying and cutting processes due to their high hardness and other characteristics. It can also be used in heavy-duty excavator drill bits.

5. We can provide customized products according to your drawings.