Tungsten Carbide Milling Cutter Button

Introduction

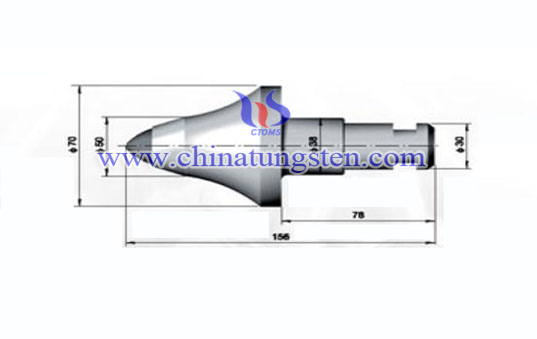

Tungsten carbide milling cutter button also to be named milling cutter blade, road tooth, roadway tooth and milling machine tool, which is the main accessories of milling cutter machine. The milling machine uses the contact of the cutter head with the ground to perform road milling operations. From the specification, it is basically divided into two types: Φ20mm and Φ22mm, which are distinguished according to the diameter of the bottom of the cutter head.

Milling cutter button is a tool to cut the ground directly, it is general composite by tungsten carbide button, cutter body, spring and card, some of them composite by tungsten carbide button, cutter body and spring.

Imported or domestic milling machines are equipped with cutter heads according to these two sizes. This is to facilitate the user to replace the cutter heads, but the shape structure is much more complicated. Each company's shape is different, but as long as it is distinguished The two major categories, the other are basically universal, the shape does not have to be in one frame, although each company has different styles in the design of the cutter head, but the idea is basically the same; that is to ensure the milling cutter head In the milling operation, it can flexibly rotate, and minimize the resistance of the cutter head during work, and quickly cut the pavement material; therefore, we do not need to consider its shape when purchasing, each company's products have its unique side.

Grade and Properties

| Grade | Density g/cm3 | Hardness HRA | T.R.S. N/mm2 | Grain Size | Application |

| K20 | 14.7±0.1 | 88.5±0.3 | 1940 | 2.4~4.0um | Used in asphalt pavement and concrete pavement, milling and mixing of gravel soil. |

| K30 | 14.5±0.1 | 87.5±0.3 | 2200 | ||

| K30 | 14.4±0.1 | 86.5±0.3 | 2400 | ||

| K10 | 14.9±0.1 | 89.5±0.3 | 1800 |