Tungsten Carbide Wedge Button

Introduction

1. Tungsten carbide wedge button is made of high purity tungsten raw material, which with high wear resistance and hardness.

2. Pressed by isostatic pressing precision press machine, with uniform density and continuous tooth.

3. Sintering with overpressure sintering furnace increases the wear resistance of the product by 24%.

4. After the centerless grinding machine fine grinding, the sizes are accurate, with more firm welding and continuous tooth.

Applications

Tungsten carbide wedge button for geology and minerals are mainly used for inlaid ball-toothed drill bits. Which are widely used in open pit mining, quarrying, hydropower engineering, drilling of water wells, and support of excavation side columns.

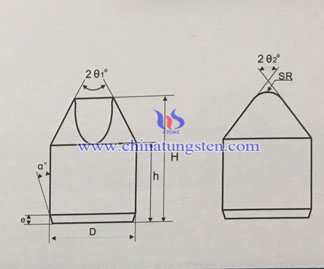

Specifications

| Type | Dimensions (mm) | |||||||

| D | H | h | 1° | 2° | SR | e | α° | |

| XX0809-E10 | 8.25 | 9.0 | 5.5 | 22.5 | 45 | 1.35 | 1.0 | 20 |

| XX1013-E16 | 10.25 | 13.0 | 9.0 | 22.5 | 45 | 2.50 | 1.6 | 18 |

| XX1115-E15 | 11.25 | 15.0 | 8.0 | 22.5 | 30 | 2.75 | 1.5 | 18 |

| XX1114A-E13 | 11.30 | 14.0 | 8.1 | 21.5 | 37.5 | 3.50 | 1.3 | 20 |

| XX1117B-E13 | 11.30 | 17.1 | 9.1 | 20 | 26.5 | 3.00 | 1.3 | 20 |

| XX1118C-E11 | 11.30 | 17.8 | 10.1 | 17.5 | 25 | 3.15 | 1.1 | 18 |

| XX1621-E20 | 16.35 | 21.0 | 11.0 | 22.5 | 35 | 2.60 | 2.0 | 18 |

| XX1623-E20 | 16.35 | 23.0 | 12.0 | 18 | 30 | 3.00 | 2.0 | 18 |