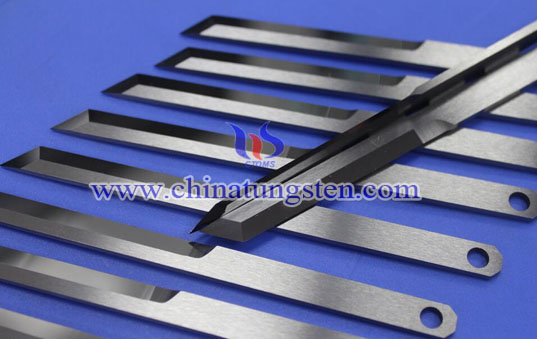

Tungsten Carbide Clothing Spreader Blade

Introduction

In order to improve production efficiency in industrial mass production, the most direct and effective form is to improve the performance of tool products. Especially for metal cutting tools, tungsten carbide clothing spreader blade is typical representatives of super-hard metals, which are the best performance of high-quality cutting tools. One of the direct tool products. Garment machinery and equipment customers traditional spreader cutting scissors are made of high-speed steel and other steel materials as the base production work, it is necessary to trim the edge and cut the edge with a belt to ensure the sharpness. In the process of tempering, the cutting edge of the tool itself is worn out, and the service life is very limited. The cutting work of large-scale fabrics, especially denim or fabrics containing other elemental materials, is very wear-resistant to traditional tools, especially in the long-term high-temperature operation, which requires frequent replacement of cutting tools.

Tungsten carbide clothing spreader blades have high hardness, high wear resistance and high temperature resistance, which is an excellent performance as a cutting tool. According to the requirements of Guangdong Garment Machinery Spreading Machine Equipment Manufacturers, the DC cutters produced by the selection of ultra-fine alloy materials can be used as the basis for custom processing according to the dimensional accuracy of the drawings.

The product performance improvement of the cutting tool will directly affect the efficiency of the garment machinery to produce cutting operations, reducing the time and frequency of frequent replacement and grinding of the blade. Of course, due to the particularity of the production and processing of cemented carbide inserts, the production cycle is relatively long, and the processing time is relatively long. Customers who have the demand for the use of tool products in this area need to arrange the time work in advance to avoid delaying the normal production time.