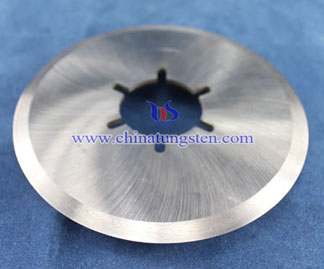

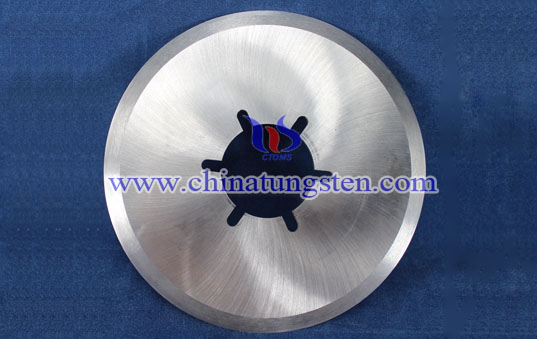

Tungsten Carbide Splitter Blade

Introduction

Tungsten carbide splitter blade is specially developed for cutting aluminum alloy materials. Whether it is the material grade or the angle of the blade edge and the grinding process, it is specially selected by professional engineers. The aluminum is cut with a cemented carbide plate cutter. The surface of the material section is not only smooth and new, no need to grind, but also has no chip and burrs, and is deeply loved by the hardware processing industry and aluminum-based circuit board manufacturers.

Finishing Grinding Process

clamping → wire cutting positioning groove → grinding inner hole → grinding plane → cutting edge → reverse batch wind → precision grinding → reverse batch wind → mirror polishing → microscope inspection cutting edge → marking → packaging

Technical Properties

1、WC Content:94.0%

2、Co Content:6.0%

3、Hardness HRA: 93.0

4、Density g/cm3:14.8

5、T.R.S. MPa:3000

6、Elastic Modulus GPa: 530

7、Thermal Expansion Coefficient 10-6/0C:4.9

8、Grain Size:0.6um