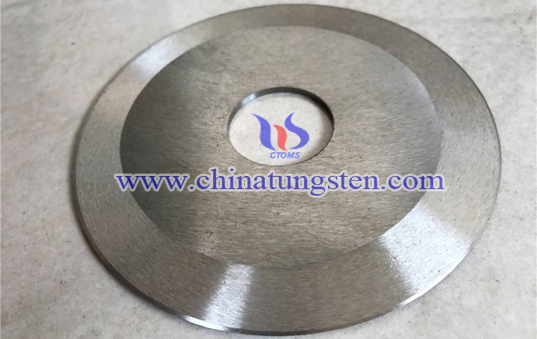

Tungsten Carbide Slitting Blade

Introduction

Tungsten carbide slitting blade is one of the most important parts of slitting machines. Improper selection of the cutting machine blade can easily cause the service life of the slitting blade to be shortened, failing to meet the requirements of the cutting index, and the cutting material generates burrs and generates a large amount of cutting dust. Therefore, cemented carbide materials are the best choice for slitting blades.

Application

Tungsten carbide slitting blade is mainly used for slitting of paper, tape, tape, film, gold, silver, copper, aluminum, and alloy foil.

Tungsten Carbide Slitting Blade Cutting Process

1. Trimming: A variety of materials are combined to form a process edge material, and the process edge material reserved by the cutting process is obtained to obtain a product that meets the process requirements. This type of slitting method is mostly used for processing materials such as composite film.

2, Cutting: The whole roll of wide coil, through the high-speed running circular knife, the original coil is cut into multiple rolls of narrow-gauge coil. This type of slitting is mostly used in the adhesive products industry.

3. Sub-volume: The large-diameter material is cut into multi-volume and small-reel diameter materials according to the requirements of the reeling length dimension and the winding width specification. This slitting method is mostly used in the film substrate and flexible packaging color printing industry.