Tungsten Carbide Soldering Machine Blade

Introduction

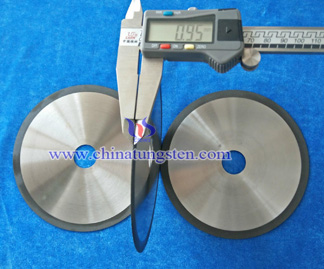

Tungsten carbide soldering machine blade is used in matching soldering equipment for cutting electronic solder wire, such as 0.3mm 0.5mm 0.8mm 1.0mm tin wire, cutting or hole on the solder wire soldered on the PCB circuit board to prevent The soldering is and the solder is sputtered out. The super-stable stability of the carbide insert can meet the requirements of various cutting working environments, especially for continuous high-temperature mechanical cutting operations. Good thermal stability can hardly cause any plastic deformation. The customized carbide soldering machine blade specification is φ22×φ10×0.3, which belongs to ultra-thin alloy blade, which is mainly used for the cutting operation of soldering equipment. The continuous and efficient work of automatic soldering equipment requires the inner hole and the outer circular blade of the insert. The concentricity is extremely high, the surface of the blade is flat and smooth, and the cutting edge is mirror-finished to ensure the cutting sharpness when the blade is running.

Tungsten carbide soldering machine blade is one of the super hard tools, also known as tungsten steel inserts. Their excellent performance as cutting tools is widely used in manufacturing and is a powerful auxiliary tool for modern industry. The thickness of the ultra-thin carbide blade produced by our company according to customer's requirements can reach 0.1MM. The ultra-thin blade is made of hard alloy material made of ultra-fine grain high-quality tungsten carbide raw material and refined by high-precision processing equipment. With good toughness and longevity. For the specific use requirements, the ultra-fine-grained carbide ultra-thin blade with a copper foil cut can be 20mm × 10mm × 0.1mm, that is, 20 × 10 × 0.1.

Application

Tungsten carbide soldering machine blade is customized for the customer's drawings of the supporting solder production equipment. The selected ultra-fine particle cemented carbide material is used as the base. The precision machining equipment is used according to the detailed parameters. The product is tested after standard inspection to ensure that each A single data meets specific standards. Our company provides custom-made services for carbide inserts, including carbide round inserts, carbide inserts, carbide long inserts, thin carbide inserts and carbide thinner inserts. Based on the customer's drawings or sample parameters, based on the specific requirements of the customer's friends, as a wealth cutting tool, to meet the customer's needs for cutting and machining of carbide inserts.