Tungsten Carbide Foil Slitting Blade

Introduction

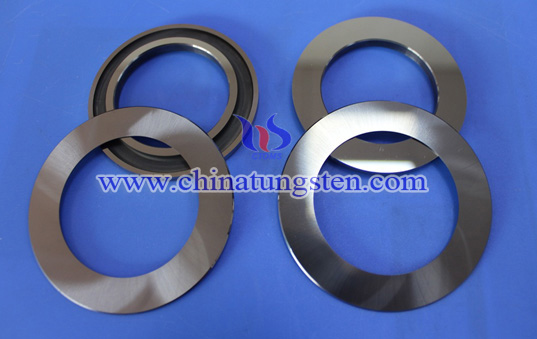

Tungsten carbide foil slitting blade is generally composed of a rewinding machine bottom knife and an upper slitting knife. The size specification of the standard tungsten carbide rewinding machine bottom knife produced by our company is: φ60*φ40*5, the upper slitting circle the knife size specification is: φ68*φ46*0.5.

Tungsten carbide foil slitting blade, selected subfine grain granular tungsten carbide powder is sintered by high temperature and low pressure after precision molding. The metallographic structure of the carbide insert has good compactness and avoids the sharpening of the cutting edge. The phenomenon of chipping occurs during use, improving the smoothness of the cutting section and the requirements of one-time cutting and forming; using a high-precision grinding machine to sharpen the cutting edge, the machining precision is high, the finish is high, the mirror effect is sharp, the cut section is smooth, smooth, no The hair has no cloak; the hardness is high, the edge is sharp, the wear resistance is good, and the working cycle of one installation is long.

Application

Copper foil is a kind of cathode electrolytic material, a thin, continuous metal foil deposited on the base layer of the circuit board, which acts as an electrical conductor of the PCB. It is easy to adhere to the insulating layer, accepts a printed protective layer, and forms a circuit pattern after etching. Copper foil has a low surface oxygen property and can be attached to a variety of different substrates, such as metals, insulating materials, etc., and has a wide temperature range. Mainly used in electromagnetic shielding and anti-static, the conductive copper foil is placed on the substrate surface, combined with the metal substrate, has excellent conductivity, and provides electromagnetic shielding effect.