Tungsten carbide glass plate is usually called wear plate, which is an important part of concrete pump, it is called glass plate as the sharp looks like glass. wear ring is also called wear rings, the sharp is for round type.

The main materials for wear plate and wear ring include high-chromium alloy, cast iron, high manganese steel, steel alloy, tungsten carbide and cermet and so on. The tungsten carbide for wear material with more higher hardness and wear resistance, but it is with greater brittleness as it is super hard material. If tungsten carbide is for wear plate, it will require the material with special composition with completely different with traditional material. Tungsten carbide wear plate not only for high hardness and wear resistance, but also with excellent impact resistance, completely meet the requirements of concrete pumps

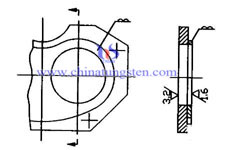

Tungsten carbide wear plate and wear ring is a pair of close coordination with the relatively moving part, the surface of these two parts coated with wear material, through the end of the spline nut opposite sex in S-shaped tube, concrete pump could adjust their gap between (0.1~0.2)mm. The rubber spring assembly in the middle of S-shaped tube and wear ring, the wear ring and wear plate will be flexible and comfortable on relative movement.

|

|

|

Tungsten Carbide Wear Plate Wear Rate and Principle

With the use of time, the rubber spring will missing elasticity, wear ring and tungsten carbide wear plate will be wearied, the gap between these two part will be increased accordingly. As soon as the gap bigger than 0.7mm, it must be adjusted, otherwise the concrete pump mortar will into the room at once. If the mortar into the room, the wear rate will be increased rapidly.

When the pumps working, the wear ring will swing according to the S-shaped tub' swing, which plays a role in cutting concrete, so the wear rate of wear ring will be increased soon, the higher pressure in exit, the wear rate will be more serious. As usual, the wear part of wear ring is in the edge, which is in the upper 90 ° angle of two symmetrical parts. So if the wear ring is wearied in the up part, it should be turned on another angle, and then continue to use, this is a kind of method for extending service life.

Tungsten Carbide Wear Plate and Wear Ring Affecting Factors

1.The difference between each site of concrete pumping. In general, a reasonable proportion of concrete (such as ready-mixed concrete), wear plate, wear ring's life will be longer. If the site using concrete, wear plate's life up to more than 1.5 Articles, but also the life of the wear ring is also between 0.8 and 1.2 Articles.

2. Each site pumping conditions differences. In height, long distance pumping concrete conditions, tungsten carbide wear plate and wear ring is bear a greater back pressure, so the shorter life expectancy.

3.The gap of tungsten carbide wear plate and wear ring will affect the life. wear ring has a great preload, which can squeeze in glasses plate. When pumping, the pump will not be able to enter the pulp. At this spectacle wear plate occur on the entire plane, wear more evenly, so the longer life expectancy. The wear ring wear occurs on the edges of the wear ring, if we can promptly adjust the direction of the wear ring to wear uniform edge, then wear ring life will be doubled. Since each work cycle will be cut with the wear ring twice, so the tungsten carbide wear plate at the bridge of the nose is the most easily accessible place small aggregates, which can easily cause the nose to wear tungsten carbide wear plate scrapped.

Therefore, concrete pump at work for some time, you should adjust the direction of the wear ring, tighten the nut straight, which will greatly extend the tungsten carbide wear plate and wear ring's life.

More Info>>

1.Tungsten Carbide

2.Tungsten carbide Balls

3.Tungsten carbide Burrs

CHINATUNGSTEN ONLINE has been specialized in manufacturing tungsten products, especially cemented carbide products for more than 20 years. If you have any inquires concerning the products in this website, please do not hesitate to e-mail us by : sales@chinatungsten.com

Tungsten Information[Tungsten Information ][Tungsten Catalogs][Tungsten Dictionary]

[Tungsten News][Tungsten Videoes Bank][Tungsten Pictures' Bank][Tungsten Directory]

Chinatungsten Group[ChinaTungsten] [Tungsten Alloy Manufacturer] [Tungsten News] [Paper Weight] [Tungsten Copper] [Tungsten] [Molybdenum Products] [Tungsten Alloy]

[Tungsten Carbide Jewellery] [Tungsten Dart] [Dart Shop] [Tungsten Fishing Sinker] [Tungsten Powder] [Tungsten Metal] [Metals Price]

Address: 3F, No.25 WH Rd., Xiamen Software Park Ⅱ, FJ 361008,China

Phone:+86-592-5129696,+86-592-5129595; Email:sales@chinatungsten.com

Certified by MIIT:闽B2-20090025 闽ICP备05002525号-1

Copyright©1997 -

ChinaTungsten Online All Rights Reserved