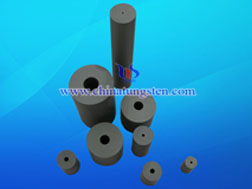

In standard parts industry, tungsten carbide cold heading dies need to under great unit pressure in cold upsetting deformation process , when a large degree of deformation and material hardness, units of pressure up to 2000MPa more. At the same time the metal flow intense, thus requiring tungsten carbide cold heading dies have high strength, good fatigue resistance, high hardness and good fatigue resistance, in order to ensure the cold heading dies under high pressure without breaking, deformation and wear resistance.Tungsten carbide cold heading die raw material is produced by powder metallurgy composite materials, which have high hardness, wear resistance,life is several times and several hundred times than ordinary cold heading die. With carbide manufacturing standard tungsten carbide cold heading die, not only have high dimensional accuracy of parts, but also greatly improve the life of the cold heading die, can create good economic and social benefits.

Carbide is made of rare and very fine particles of refractory carbide (WC) and metallic cobalt as a binder composition. Due to the special method for producing such alloys remains the original characteristics of the tungsten carbide, its hardness close to diamond, and because of cobalt as a binder, it also has the toughness. Tungsten carbide cold heading dies material has the following characteristics:

1. High wear resistance. Tungsten carbide cold heading dies material high wear resistance, tensile modulus can be guaranteed long-term work in any degree of deformation, ensuring standard size unchanged.

2. Excellent in polishing. Carbide has a good polishing, can be processed into the die hole mirror light, ensuring high quality standard surface.

3. Adhesion to metal is small. In the tungsten carbide cold heading process, ferrous metal material adhesion small carbide tooling materials, ensuring a high tungsten carbide cold heading die life.

4. The friction coefficient and energy consumption is small.

5. High thermal conductivity. Since the thermal conductivity of the tungsten carbide die is high, heat generated during the cold forging can quickly conducted away to improve the durability of the mold.

6. Good corrosion resistance.

Tungsten carbide grade selection

In the standard tungsten carbide cold heading process, tungsten carbide cold heading die need to withstand greater shock, in order to meet the requirements, you must use the tungsten carbide with a higher amount of cobalt-containing, high strength and good toughness. Such as YG15, YG20, YG20C .

Rapid deformation of the metal and the inner friction of the workpiece temperature may rise above 200℃, tungsten carbide cold heading dies should be able to work a long hardness remains constant at this temperature, extrusion, can withstand hot and cold alternating stress and still have good fatigue resistance in a continuous upsetting,. In order to improve tungsten carbide cold heading die used life, can adopt different measures, such as improved lubrication conditions, design an reasonable shape of tungsten carbide cold heading die , reducing roughness values, so as to improve processing quality of carbide tungsten carbide cold heading die.

Because tungsten carbide cold heading die material has many features, and its life expectancy is 40 to 60 times , even up to 200 times to the overall structure of the die life. So, Tungsten carbide is a cheap, ideal material for tungsten carbide cold heading die.

More Info>>

1.Tungsten Carbide

2.Tungsten carbide Balls

3.Tungsten carbide Burrs

4.Tungsten Carbide Inserts

5.Tungsten Carbide Plates

CHINATUNGSTEN ONLINE has been specialized in manufacturing tungsten products, especially cemented carbide products for more than 20 years. If you have any inquires concerning the products in this website, please do not hesitate to e-mail us by : sales@chinatungsten.com

Tungsten Information[Tungsten Information ][Tungsten Catalogs][Tungsten Dictionary]

[Tungsten News][Tungsten Videoes Bank][Tungsten Pictures' Bank][Tungsten Directory]

Chinatungsten Group[ChinaTungsten] [Tungsten Alloy Manufacturer] [Tungsten News] [Paper Weight] [Tungsten Copper] [Tungsten] [Molybdenum Products] [Tungsten Alloy]

[Tungsten Carbide Jewellery] [Tungsten Dart] [Dart Shop] [Tungsten Fishing Sinker] [Tungsten Powder] [Tungsten Metal] [Metals Price]

Address: 3F, No.25 WH Rd., Xiamen Software Park Ⅱ, FJ 361008,China

Phone:+86-592-5129696,+86-592-5129595; Email:sales@chinatungsten.com

Certified by MIIT:闽B2-20090025 闽ICP备05002525号-1

Copyright©1997 -

ChinaTungsten Online All Rights Reserved