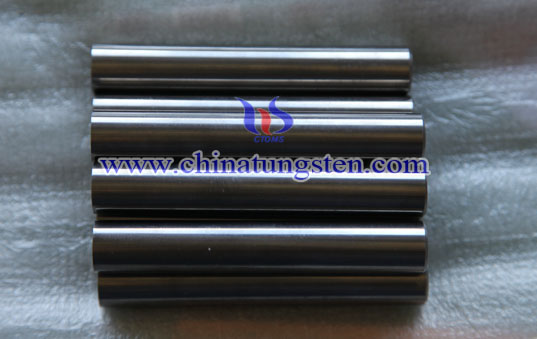

Precision Ground Tungsten Carbide Rod

Introduction

The surface of precision ground tungsten carbide rod is with polished condition, which has been ground to achieve the precise shape and size, and has a precision tolerance. The tungsten carbide round rod provides high wear resistance, and good corrosion and heat resistance. Tensile strength, used to indicate the material's overall strength, is the peak stress it can withstand before it breaks. Corrosion resistance describes the material's ability to prevent deterioration caused by atmosphere, moisture, or other medium. Wear resistance indicates the ability to prevent surface damage caused by contact with other surfaces. Hardness describes its resistance to permanent surface deformation.

Features

1. Degree of finishing is over grade9, and diameter tolerance is -0.013.

2. Material includes K10, K20, K30 and K40F.

3. Undertaking order of non-standard size work.

Application

The uses of tungsten carbide rods are divided into two parts: on the one hand they are used to produce finished hardmetal tools, such as twist drills, mills, reamers, taps and burrs etc; on the other hand they are applied to produce processing tools of making printed circuit boards (PCB), such as micro-drills, big-head drills and gravers etc.

The grade of YG6, YG6X, YG8 is better wear resistant than MK6, it can used for hard wood, processing original wood aluminum section bar, brass rod and cast iron, etc. The grade of YG10 is wear and percussion resistance, used for processing hard wood, soft wood ferrous and non-ferrous.