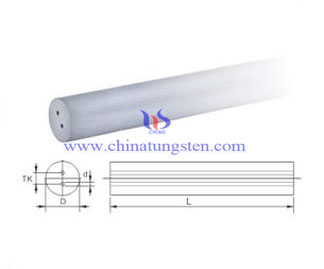

Tungsten Carbide Two Straight Shrinkage Rod

Introduction

Tungsten carbide two straight shrinkage rod is a kind of ccarbide cutting tool, which is suitable for different roughing parameters, cutting materials and non-metallic materials. At the same time, tungsten carbide two straight shrinkage rod could also used in traditional automatic, semi-automatic lathes and so on.

Processing

Tungsten carbide two straight shrinkage rod main processing is powder→ burden→ wet milling→ mixing→ smash→ dry→ sieved→ added forming agent→ dry again→ after sieving prepared mixes→ granulation→ suppress→ forming→ low pressure sintering→ forming(blank) →drilling→ polishing→ checking→ package→ warehousing

Application

Tungsten carbide two straight shrinkage rods are widely used in drills, end mills, reamers. It can also be used for cutting, punching and measuring tools. It is used in paper, packaging, printing, non-ferrous metal processing industry. In addition, it is widely used in high speed steel cutting tools, carbide cutters, carbide cutting tools, NAS cutting tools, air tools, carbide drill bits, cutter core drill HSS, taperd cutter, Metric cutter, micro end milling cutters, reamers pilot, electronic tools, step drills, metal cutting saws, double guarantee diamond, guns, angle cutters, carbide burrs, carbide cutting tools.

Tungsten carbide two straight shrinkage rod grades YG6, YG8, YG6X are more resistant than MK6, can be used in hard wood, processed aluminum extrusions, brass rod and cast iron, YG10 grade wear resistance, percussion for the processing of hard wood, soft wood, ferrous and nonferrous metals.

Code

Code:ØD×2Ød×TKØ×LZ (L means length, Z means two straight holes)

| OD (mm) | OD Tol. | Hole Size | Hole Tol. | Hole Spacing | Spacing Tol. | Hole Deviate |

| Ø6.3 | 0~+0.3 | 1.0 | ±0.10 | 3.0 | -0.2 | 0.15 |

| Ø8.3 | 1.0 | ±0.15 | 4.0 | -0.3 | 0.15 | |

| Ø10.3 | 1.4 | ±0.15 | 5.0 | -0.3 | 0.20 | |

| Ø12.3 | 0~+0.4 | 1.75 | ±0.15 | 6.0 | -0.5 | 0.30 |

| Ø14.3 | 1.75 | ±0.15 | 7.0 | -0.5 | 0.37 | |

| Ø16.3 | 2.0 | ±0.20 | 8.0 | -0.5 | 0.40 | |

| Ø18.3 | 0~+0.5 | 2.0 | ±0.20 | 9.0 | -0.8 | 0.50 |

| Ø20.4 | 2.5 | ±0.25 | 10.0 | -0.8 | 0.5 |