What is the mandrel

Mandrel is a very long rod and head as in the deformation zone deformation participate pipe, except that when the needle breast mandrel inside the tube with the pipe while rotating axial moving; vertical Sapporo (rolling tube, period-style rolling, the top tube) when the mandrel does not rotate, but also with the cylinder axial movement.

On the floating mandrel and MPM machine, the mandrel is an important tool, which in addition to the requirements of high-strength and high wear resistance of the material making, but also requires a very high surface quality, such as after turning to After grinding and heat treatment. Top tube of the mandrel used should be able to withstand a lot of jacking force. Oblique rolling machine mandrel Rally mandrel, floating mandrel, retained mandrel and mandrel type rollback and so on.

Rally axial movement of the mandrel is working faster than the speed of the axial movement of the tube mandrel, mandrel pulling force on the inner surface of the tube. Rollback type axial movement of the mandrel is the direction of the mandrel and the tube axial movement in the opposite direction, Shijiahoula force of the mandrel. Oblique Rolling machine for mandrel requirements lower than the longitudinal extension of the machine to roll.

|

|

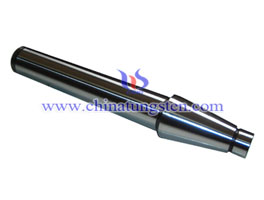

What is Tungsten Carbide Mandrel

Tungsten carbide mandrel is a smaller version of the mandrel, the mandrel standard carbide overall length always are less than 100mm, the main length is 80mm. But if the customers have special required about the size, we could provide the mandrel according to different customer requirements. Tungsten carbide mandrel is mainly used in the pressing direction of the mandrel in the compact or the sintered body forming mold parts Profile.

Tungsten Carbide Mandrel Application

Ordinary materials of mandrel are mainly for the production of seamless pipe when inserted into the body with the interior annular grooved rolls or the like so that the pipe forming tool. Continuous rolling machine rolling, pipe rolling ramp extended period type rolling machine rolling, you must use a mandrel head pipe and tube when cold-rolled cold drawn.

Tungsten carbide mandrel, as special nature of the material, and carbide materials prices are relatively high, so it is usually used in the main oil bearing plants, metallurgy plants, tool factory and relatively high-end products.

Tungsten Carbide Mandrel Features

1. Mirror-polished, surface finish to Ra0.02μm.

2. The outer diameter of the precision required to achieve 0.001mm, roundness to within 0.5μ.

3. Size can be made according to customer specified to make a variety of specifications; the minimum outside diameter can be processed Φ0.2mm size.

4. Tungsten carbide mandrel is characterized by material wear, very suitable for oil-bearing plants, metallurgy plants, and tool factory.

CHINATUNGSTEN ONLINE has been specialized in manufacturing tungsten products, especially cemented carbide products for more than 20 years. If you have any inquires concerning the products in this website, please do not hesitate to e-mail us by : sales@chinatungsten.com

Tungsten Information[Tungsten Information ][Tungsten Catalogs][Tungsten Dictionary]

[Tungsten News][Tungsten Videoes Bank][Tungsten Pictures' Bank][Tungsten Directory]

Chinatungsten Group[ChinaTungsten] [Tungsten Alloy Manufacturer] [Tungsten News] [Paper Weight] [Tungsten Copper] [Tungsten] [Molybdenum Products] [Tungsten Alloy]

[Tungsten Carbide Jewellery] [Tungsten Dart] [Dart Shop] [Tungsten Fishing Sinker] [Tungsten Powder] [Tungsten Metal] [Metals Price]

Address: 3F, No.25 WH Rd., Xiamen Software Park Ⅱ, FJ 361008,China

Phone:+86-592-5129696,+86-592-5129595; Email:sales@chinatungsten.com

Certified by MIIT:闽B2-20090025 闽ICP备05002525号-1

Copyright©1997 -

ChinaTungsten Online All Rights Reserved