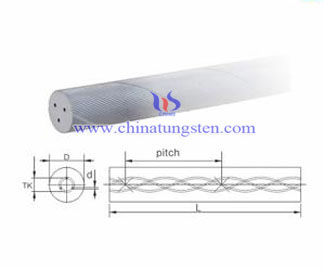

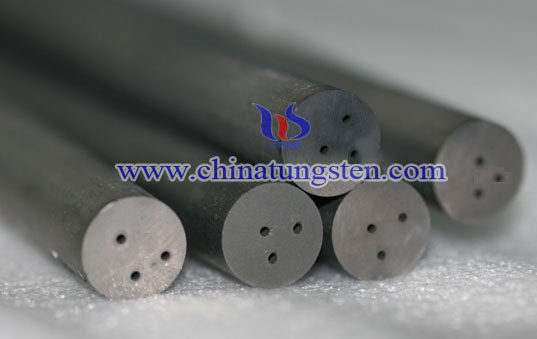

Tungsten Carbide Three Spiral Holes Rod

Introduction

Tungsten carbide three spiral holes rod with stable mechanical properties, easy to weld, high wear resistance and impact resistance, are widely used to make drill, end mill, thread drills, reamers and so on. Suitable for the manufacture of tungsten carbide various tools, machining heat-resistant alloys and titanium, are also suitable for processing steel HRC <40. Tungsten carbide three helix holes rods to be processed as part of the cooling process. Chinatungsten online could provide quality carbide three helical rods, the main product is 30°three spiral holes rod.

Features

Stable mechanical properties, easy to weld, high wear resistance and impact resistance.

At a temperature of 500 ℃ also remained unchanged, at 1000 ℃ still very high hardness.

With high hardness, wear resistance, high temperature stable performance advantages.

Advantages

- Low pressure sintering technology, stable quality and reliable: The maximum pressure up to 100 kgs sintered alloy internal pores can be effectively eliminated, thereby obtaining a good densification of high hardness, high strength rough, advanced temperature control system can effectively reduce quality fluctuations.

- Using automatic overpressure relief extrusion equipment, various types of bars can be produced: the use of imported automatic extrusion equipment, the regulator can according to different requirements, is conducive to the production of different types of bars.

- High precision, up to a mirror effect: CNC grinding machine, with the largest polishing rate can quickly remove the damaged layer produced when polished, improve surface finish, up mirror effect.

Application

- Making solid tungsten carbide cutting tools.

- Making processing PCB micro-drilling.

- Making carbide mandrel and other wear-resistant parts.