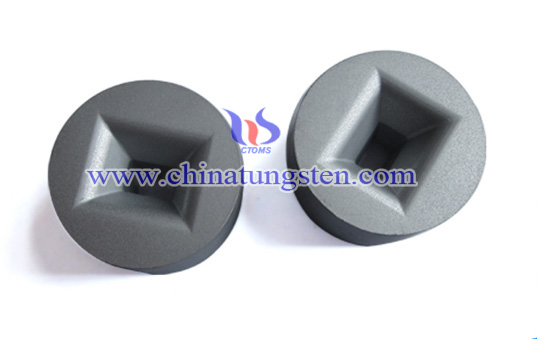

Tungsten Carbide Flat Wire Mould

Introduction

Tungsten carbide flat wire mould is a type of mould. As the speed development of automobile and motorcycle industry, the die casting industry has ushered in a new era of development. At the same time, it also puts forward higher requirements on the comprehensive mechanical properties and life of flat wire molds.

Among the various molds, the working conditions of the flat wire mold are more demanding. Pressure casting is to make the molten metal fill the mold cavity under high pressure and high speed and die-casting. It is repeatedly contacted with hot metal during the working process. Therefore, the flat wire mold is required to have high heat fatigue resistance, thermal conductivity, wear resistance and resistance. Corrosion, impact toughness, red hardness, good release properties, etc.

Choose a manufacturer of professional flat wire mold parts with good reputation, high technology and rich experience. The die-casting mold part is a special precision long-life machining part. We need professional precision machine tools suitable for the production of flat wire molds, which can ensure the dimensional accuracy of the parts. Our company has experienced senior parts manufacturing technicians, and the technician's rich experience is the guarantee of the precision of the flat wire mold parts; we are with the material supplier and heat treatment. The factory has a close relationship. Our die-casting materials are selected from Yishengbai 8407, Hitachi SKD61, Datong DH2F, etc., and supplemented by QPQ processing, DLC, TD treatment, which greatly improves the wear and corrosion resistance of the products and improves the service life up to 2 More than double.

Application

Tungsten carbide flat wire moulds are mainly used for deep drawing, with fracture resistance and deformation resistance. They are suitable for drawing and aligning bars and pipes of steel, non-ferrous metals and their alloys, as well as for manufacturing mechanical parts, tools and fragility. Parts (such as nozzles, tips, guides, forging dies, and piercing tools).