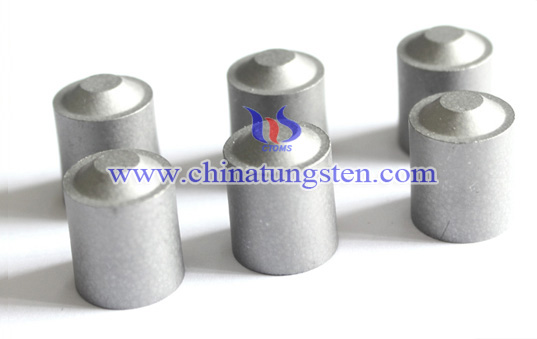

Tungsten Carbide Punch Die

Introduction

The punch is also called a punching needle, a punch, a male mold, an upper mold, etc., and the punch is a part in the mold for molding the inner surface of the product, that is, a part having a shape as a working surface. The main function is used to shape the inner surface parts of the product, that is, the parts whose outer shape is the working surface.

Tungsten carbide punch die uses a good molding technique to make punches of various complex shapes, which can be organized according to the user's drawings. The product has small deformation and high precision, and its impact toughness is superior, and the number of impacts is not increased, and the number of impacts is increased by 15%.

Tungsten carbide punch die is a stamping die that processes a material into a part (or semi-finished product) in a cold stamping process. Punches are a type of pressure processing method that uses a mold mounted on a press to apply pressure to the material at room temperature to cause separation or plastic deformation to obtain the desired part.

Tungsten Carbide Punch Die Wear

In the process of punching, the factors of invalid including wear and break, the relative motion of the mold to the workpiece (sliding, rolling, or rolling + sliding) creates friction, which can cause wear of the mold. When the wear of the mold reaches a certain level, it will seriously affect the surface quality and dimensional accuracy of the machined workpiece, resulting in mold failure. At this time, it is necessary to sharpen the mold or replace the new mold.

Advantages

The use of tungsten carbide materials can reduce the surface roughness value of the mold, strengthen the surface treatment of the mold, and improve the wear resistance of the mold, which not only saves energy and reduces cost, especially the life of the mold is prolonged.