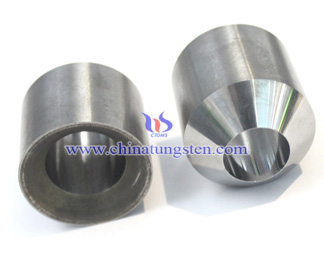

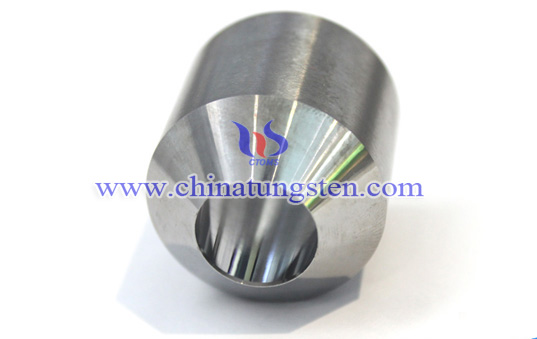

Tungsten Carbide Suede Mold

Introduction

1. It can produce 0.8mm-80mm cemented carbide skin mold.

2. Used to strip oxide, viscous or other coatings on the surface of metals such as copper, aluminum, and steel.

3. It can be produced and processed according to the drawings provided by customers.

Application

Tungsten carbide suede mold is mainly used to strip oxide, dirt or other coatings on metal surfaces such as copper, aluminum and steel.

Tungsten Carbide Suede Mold Grade, Properties and Application

Grade |

Density |

Hardness |

T.R.S. |

Application |

YG6X |

14.8-15.1 |

≥91 |

≥1420 |

Suitable for drawing steel wire with a diameter of 6.0mm or less, non-ferrous metal wire or bar under the condition of low stress. |

YG6 |

14.7-15.1 |

≥89.5 |

≥1520 |

Suitable for under-stress conditions, drawing diameters below 20mm Wire, non-ferrous and alloy bars, also suitable for drawing pipes with a diameter of 10 mm or less. |

YG8 |

14.6-14.9 |

≥89 |

≥1470 |

Suitable for wire drawing calibration of steel, non-ferrous metals and alloy bars and tubes, as well as for the manufacture of mechanical parts, tools and consumable parts. |

YG8.2 |

14.4-15.0 |

≥88 |

≥1450 |

|

YG8L |

14.6-15.0 |

≥89 |

≥1450 |

|

YG15 |

13.9-14.2 |

≥86.5 |

≥2060 |

Suitable for top steel hammers, perforations and punching tools for steel bars and steel tubes with high compression ratios and working under large stresses. |