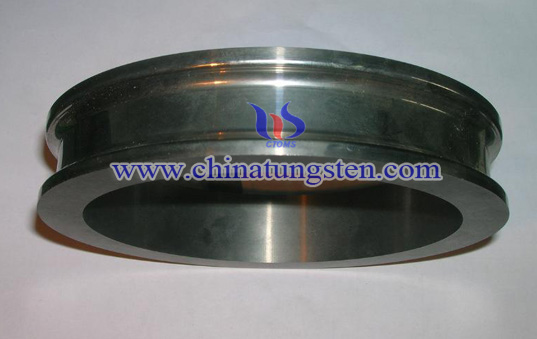

Tungsten Carbide Forming Dies

Introduction

The tungsten carbide for the integral mold is a carbide with a low cobalt content---tungsten-cobalt alloy, which has good wear resistance, impact resistance, polishing and corrosion resistance, is easy to repair, and is inexpensive, it is the common wire drawing core manufacturing materials, widely used in the stretching of coarse and medium wire.

Production Process

The study indicated that after improving the composition and structure of the tungsten carbide, manipulating the shake value of the carbon content and refining the particles of the carbide, the function of the raw material can be improved, and the service life can be extended. Now, the use of hot isostatic pressing (HIP) treatment, ultra-fine crystal technology and participation in rare earth elements to reduce porosity, refine grains, improve the hardness of the alloy, reduce the friction coefficient; and use chemical vapor deposition (CVD) And the physical vapor deposition (PVD) method forms a diamond film or a titanium nitride coating on the outer surface of the tungsten carbide to improve the appearance strength of the alloy.