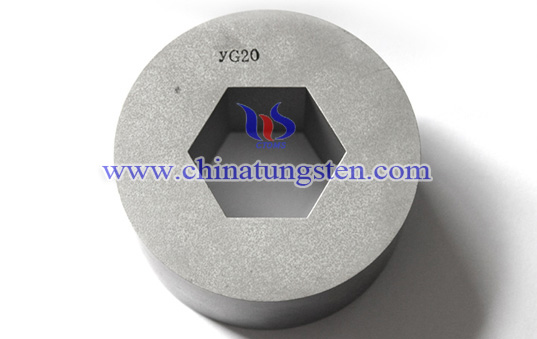

Tungsten Carbide Hexagonal Nut Cold Die

Introduction

1. Using good carbide raw materials and mature processing technology to ensure the service life of the products.

2, long service life: the raw materials use special technology, adding wear-resistant element materials, so that the life of the mold is greatly improved.

3. Lower processing cost: It is pressed by imported press and sintered by over-pressure sintering furnace. The product has a perforated shape, small tolerance of external dimensions and lower processing cost.

Application

Tungsten carbide hexagonal nut cold die is mainly adapted to the standard room of cold heading cold copper, aluminum, steel and alloy steel, screws, rivets, etc., flat head cold die, countersunk head cold die, first order punching die, Commonly used models such as shrinking bars.

Processing Five Guarantees

1. Advanced powder metallurgy mounting equipment and technology make the cold die core and die set perfectly combined.

2. Advanced laser perforation equipment ensures the accuracy of the hole shape of the cold die.

3. The high-speed line polishing machine polishes and controls the precise size of the sizing area.

4. Advanced ultrasonic grinding and polishing machine to ensure the precision of the cold boring die and high-quality polishing.

5. Sophisticated testing equipment and strict quality inspection to ensure the high quality of cold heading mold.